• Off-odors

• Off-flavors

• Off-colors

• Free fatty acids

• Polar compound formation

Frying oil is susceptible to many unfavorable conditions. In response, oil manufacturers have continuously pursued techniques to enhance its stability. Processors of fried foods are presented with the challenge of balancing the health demands of consumers, frying process efficiency, and finished product stability. It Oil Purifier keeps frying oil fresh, fried product light and crisp, while never discarding a drop of frying oil.

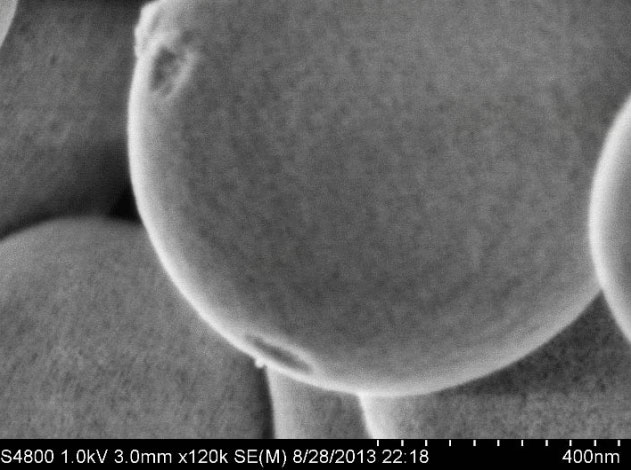

Filter paper, screens, or cartridges can only remove crumbs and debris. In order to best maintain high quality frying oil, it is necessary to remove not only the debris, but also the soluble degradation products that cause off-flavors, odors, and color in frying oil and the finished product you fry. It forms a filter cake that removes the debris and absorbs the soluble degradation products that are formed during the frying process. It has been proven to maintain frying oil and finished product quality for over 20 years and is the global benchmark for oil management.

* Because of the high value of free fatty acids, frying oil has to be discarded every 2-3 days.

* Polymer aggregates at the contact interface of frying oil, emulsifying, high thermal energy consumption

* Food color and odor are different due to the length of frying oil used

* Fried food workshop is made up of smoke, which needs energy to deal with odor.

* Provide crisp, golden delicious fried food

* Increased profits and 50-70% savings in frying oil procurement costs

* Simpler worker operation

* Environmental protection, no more smoke

* Ensure the taste of fried food

* Products with longer shelf life

* Fried oil FFA, TPM, color, taste and odor are easier to manage.